PENKO offers high quality, cost-saving solutions for Machine Automation, including ready-made or customized products which can be created specifically for your needs. Our certified electronics have been specially developed with PENKO’s 45+ years of expertise in the industry. We will provide a fast delivery of a complete system without having to wait on external parties, saving you time, money and giving you the best service.

Filling & Packaging

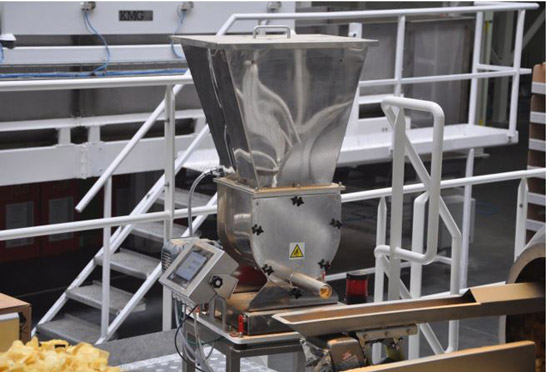

Filling a package is done by adding goods to a package. PENKO offers various solutions which enable particularly fast and precise filling and packaging in the industrial production process. The method used for filling a package depends on the type of product and the packaging required for that product. Solids are normally packed in sacks and boxes and filled on weight/mass, whereas liquids are packed in bottles, barrels or cans and filled on volume and then checked on weight to ensure they are filled with the correct volume. The filling process itself can be carried out both manually and automatically.

Why filling on weight?

Weighing on mass has the advantage that the weight remains correct, regardless of external influences such as aeration and product temperature. PENKO’s fast and accurate weighing capability will reduce the time spent for filling on your process line to the necessary minimum. It is also possible to set tighter tolerance limits which ensures correct filling and precise dosing.

As filling processes are typically done in a matter of seconds opposed to minutes, fast and precise measurement becomes important. Dosing too much may result in profit loss and product spillage, dosing too little results in unhappy customers.

PENKO’s filling ranges are specifically focused to solve this problem. State-of-the art filtering processes can easily cushion the external influences, without slowing down the weighing speed or affecting the accuracy. Users can be sure that packages are rapidly filled within tolerance.

All PENKO’s Filling ranges offer specialized solutions for filling and packaging applications. PENKO distinguishes between two versions:

- Accurate measurements at high speed

- User friendly measuring equipment with the latest technology

- Easy integration in process control systems with available software protocols

- PENKO’s Data Reporter software allows easy transfer of data to Windows based programs

- Increased production capability with Kinetic Energy Blind Time

- Increase profitability of your machines

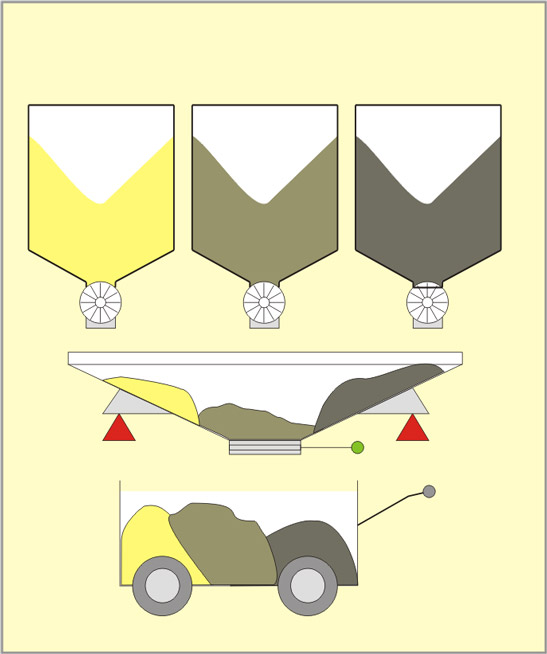

Batch Processing

At PENKO, we create batching products with a consistent composition and quality, registering the exact amount per component added to the batch allows for repetition. Batching is the process of adding components together in a specific order to create a product. The amount of product that is created in one full ‘components adding’ session is called a batch. The components can be added automatically, manually or a mixture of both options, and the amount can be either very large or very small. The batching process is used in filling, dosing and mixing applications.

Registration can be done by weighing the components. When all components dose into the same weighing hopper and the weights are within the maximum weighing capacity of the hopper, one weighing system can be sufficient. The smallest dosed amount determines the maximum weighing capacity of the hopper. For example: baking a cake – where the amount of eggs determines the amount of the other ingredients added.

PENKO’s weighing equipment can be used for all possible adding actions; automatically or manually, with a large amount or small amount. It allows for product quality enhancement by creating a repeatable consistency and can also help to minimize product spillage and save money. This can especially be the case when precision measurement equipment is used. With precision measurement the weight determination is done quicker, which leads to a smaller weight deviation and more accurate determinations. Using precision measurement equipment can further increase the profitability of a batching system.

PENKO’s weighing products are designed with the core values of precision weighing, measuring swiftness and quick signal stability; ensuring fast, reliable and accurate measurements. With our specialized functionalities for filling, dosing and mixing, we offer the possibility to incorporate high speed niche weighing technology into production lines.

Our powerful Omega controller is designed to control multiple parallel processes and is therefore very suitable for batching processes. Its high-speed weighing cards, with separate processing capability, are ideal for precision measurement.

Explore Our Products

All PENKO's Filling ranges offer specialized solutions for filling applications.

Omega

Check Weighing

PENKO has developed check weighing solutions which provide fast and precise control in the i.p.v. industrial production process. As the name suggests, check weighers are used to check the weight of goods. They are automated systems that check the products for internal control as well as for trade. PENKO’s high weighing accuracy allows for a reduction of product spillage which can be accomplished by setting tighter tolerance bands.

Types of check weighing

Both types of check weighing – category Y systems and category X systems can be used in a static as well as a dynamic environment. PENKO’s check weighing range is specifically focused to solve the problem that dynamic environments have in calculating exact weight measurements due to goods being in motion. Our state-of-the art filtering processes can easily cushion the external influences, without slowing down the weighing speed or affecting the accuracy. Users can be sure that only the desired mass will be achieved in the production process.

All PENKO’s Filling ranges offer specialized solutions for filling applications. PENKO distinguishes between two versions:

- PENKO’s SGM800 filling range and 1020 filling range are designed to switch from coarse to fine dosing just before the setpoint is reached. This switch results in dosing with great accuracy, reducing over- and underfilling to a minimum.

- PENKO’s FLEX filling range has, next to switching from coarse to fine dosing just before the setpoint, also the capability to automatically correct the inflight. This combination ensures extreme accurate dosing. Product spillage will be reduced even further.

PENKO check weighing solutions offer:

- Precise and stable check weighing instruments

- Accurate measurements at high speed

- Sophisticated filtering and signal processing

- Less delays to your operation

- Tight tolerance bands which reduce product spillage

- Easy integration in process control systems with available software protocols

- PENKO’s Data Reporter software allows easy transfer of data to Windows based programs

- Increased production capability and profitability of your machines

Continuous Weighing

For processes that require a continuous feed of material, Loss-In-Weight (LIW) systems are used as well as belt weighing. PENKO offers continuous weighing solutions for applications which enable precise control of their flow. The measuring method corrects flow inconstancies giving the best flow regulation possible. The PENKO approach ensures a continuous and precise flow which focuses on precise product dosing and consistent product quality.

A unique feature of PENKO’s continuous weighing solution is the possibility to store multiple components with its own specific weight and settings. The advantage of this recipe bank is that switching between components take far less time and the chance of making errors will be significantly reduced. As a result of that the production capacity will increase and the product spillage will reduce. PENKO’s state-of-the art filtering processes can easily cushion the external influences, without slowing down the weighing speed or effecting the accuracy. Users can be sure that a precise flow will be used in the on-going production process.

PENKO’s continuous weighing range offers specialized solutions for LIW processes.

PENKO’s FLEX Loss-In-Weight range is developed for accurately measuring the loss in weight over a certain period of time (flow). It is designed to automatically switch during filling from gravimetric to volumetric filling, ensuring a continuous product flow.

PENKO’s Continuous Weighing solutions offer:

- All high PENKO standards for speed, accuracy, filtering and signal processing

- Fast, precise and stable flow controllers

- User friendly measuring equipment with the latest technology

- Easy integration in process control systems with available software protocols

- PENKO’s Data Reporter software allows easy transfer of data to Windows based programs

- PENKO’s way of working ensures continous and precise flow, increased production capability and reduced product spillage

Force Measurement

PENKO offers a variety of force measurement tools which are bi-directional and can be used for both tension as well as compression measurements. Force measurement is the quantifying of a certain load in Newton, independent of gravity. Our instruments measure at high speed (1600s/s) with a high internal resolution (24bits), which enables them to make extremely accurate measurements. The high measuring speed of PENKO’s force measurement tools also have the advantage of reacting within milliseconds to protect your machine from overloads.

The PENKO1020 FMD has a trend indication readout value (TIR) function. This function shows the decrease or increase (slope) of the force per unit of time and can be used to monitor the force introduction for ropes, chains or concrete elements.

The FLEX Force series don’t contain TIR functionality, but allow for storing 2 force ranges. Due to the possession of two separate amplifiers, this feature comes out best using the FLEX Force 2channel controller. Storing 2 force ranges has the advantage that it increases the measuring range of the force measurement itself. It can also be used when you’re testing different sizes of materials, reducing the need to reprogram the measuring machine.

PENKO's force measurement devices offer:

- Accurate measurements at high speed and internal resolution.

- Use for both compression and tension measurements.

- Productive operation with fast reaction times

- Easy integration in process control systems with available software protocols

- PENKO’s Data Reporter software allows easy transfer of data to Windows based programs

- Increased production capability and profitability of your machines

Motion Compensated Weighing

Accurately weighing produce on board a sea-going fishing vessel is no easy task. PENKO Engineering developed a weighing system to compensate for external forces such as the waves causing the ship to pitch and roll or the motors, and hoists etc. creating a multitude of vibrations to the internal harmonics. PENKO’s Motion Compensated Weighing system offers clever digital filtering as well as unparalleled high measuring speed and high internal resolution.

Reliable weighing data from PENKO’s equipment allows for accurate batch weighing of the catches at sea. In practice, this ensures that the batches are prepared with an exceptionally high accuracy and there is less chance of overfilling with excess product. This, in turn, saves freezing capacity and related costs as well as facilitating a more sustainable environment.

PENKO's Motion Compensated Weighing System offers:

- Accurate and immediate weighing information about the batches and catch quality

- Efficient suppression of engine vibrations, unaffected by rolling and pitching

- Simple system to integrate into existing transport set up

- High protection class: IP68

- Efficient loading of freezers

- Advanced technology with database of weight information

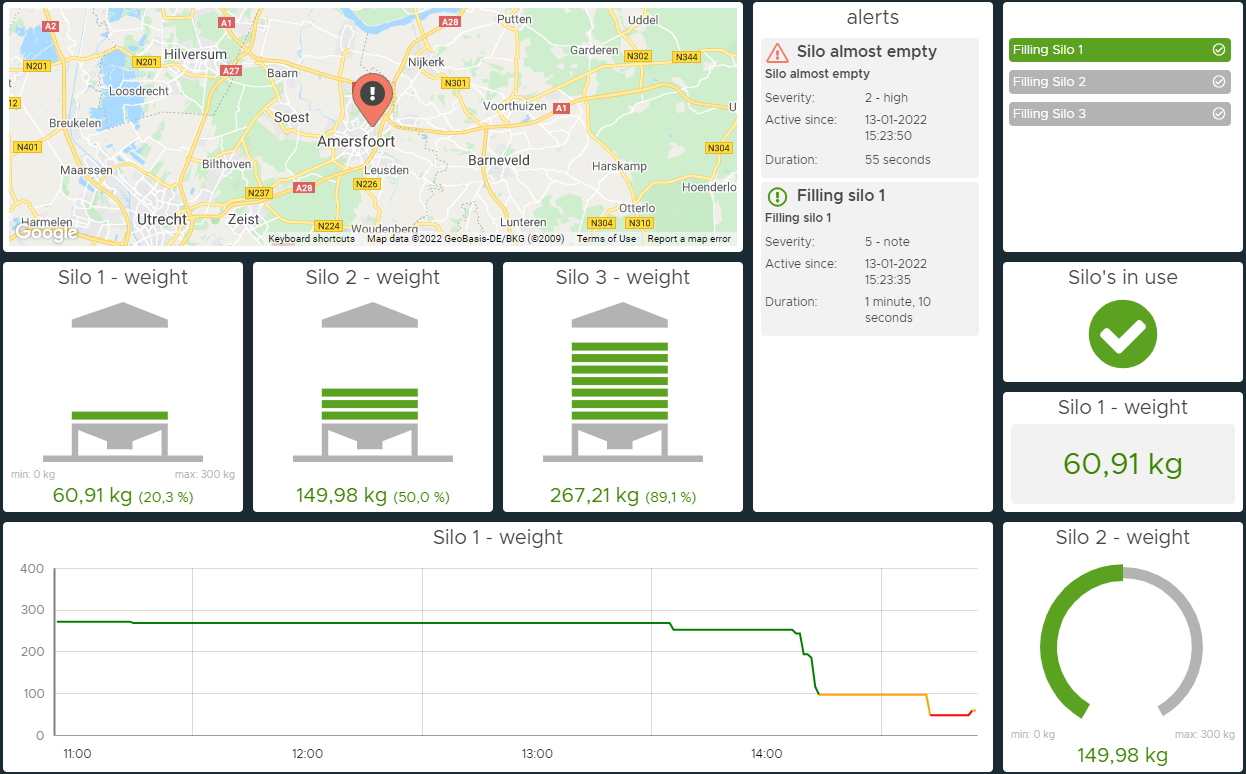

Data Management

Integrating data management as part of the supply chain can give useful insights about your products and your company’s processes. PENKO’s Data Management allows monitoring and control of each process and understanding what is happening makes it possible to create a cost-efficient product with a consistent quality on time.

PENKO solutions include:

Data Reporter

Data Reporter is a Windows based weighing data registration software, created to give you full insight into your weighing data. The weighing data is easily transferrable to (Windows based) programs suitable for further analysis.

Cloud Solutions

With PENKO’s Cloud Solutions we offer a platform with collective accessibility for sharing and access your data at any time from any place. The cloud solution can be used for monitoring your processes, predictive maintenance, etc.

PENKO's Data Management offers:

- Cost efficiency from a more efficient, streamlined production process.

- Forecasting production and purchasing needs based on the supply chain information, aligning your supply & demand and allowing for reduced product spillage.

- Real time management through tracking and tracing a specific order during the production process. Real-time management creates the opportunity to handle crucial moments during the process and preventing smaller issues turning into major ones.

- Quality control through management of the production process. The quality is enhanced by pin-pointing inconsistencies and optimizing the production process.

- Efficient loading of freezers

- Predictive maintenance through monitoring of the machines and ensuring the maximum life span of its parts are achieved thereby reducing machine downtime and costs.